7 Essential Tips for Choosing the Best Excavator Engine Parts

When it comes to maintaining optimal performance and longevity in your excavator, selecting the right Excavator Engine Parts is crucial. The engine is the heart of any heavy machinery, providing the power needed to accomplish tough tasks in challenging environments. However, with the myriad of options available, it can be daunting to choose parts that not only fit properly but also enhance the overall efficiency of your excavator. This blog will guide you through seven essential tips to help you navigate this process, ensuring that you make informed decisions that will lead to improved performance and reduced downtime. From understanding compatibility and quality to considering cost-effectiveness and sourcing reliable suppliers, these tips are designed to equip you with the knowledge needed to choose the best Excavator Engine Parts for your specific needs.

Understanding the Importance of Quality Excavator Engine Parts in Heavy Machinery

When it comes to heavy machinery, the engine is the heart of an excavator, and its performance heavily relies on the quality of its components. High-quality engine parts ensure optimal efficiency, longevity, and reliability. Poor-quality components can lead to frequent breakdowns, costly repairs, and, ultimately, project delays. Therefore, understanding the importance of selecting top-tier parts is essential for anyone looking to maximize their investment in excavators.

Quality excavator engine parts also play a critical role in maintaining safety standards on construction sites. When engines operate effectively and efficiently, it minimizes the risk of accidents caused by engine failure. Investing in reputable brands or manufacturers is a safeguard, ensuring that the parts meet rigorous standards and are compatible with various excavator models. Beyond performance and safety, high-quality parts can significantly reduce maintenance time and costs over the lifespan of the equipment, making it a smart choice for heavy machinery operators.

Specific Applications of Excavator Engine Parts in Construction and Mining Industries

In the construction and mining industries, the performance and reliability of excavator engine parts are crucial for operational efficiency. A recent report from the Construction Equipment Industry Association (CEIA) highlights that excavators account for approximately 25% of total heavy equipment sales, underscoring their importance in both sectors. High-quality engine parts directly influence the overall productivity, durability, and fuel efficiency of excavators, which can lead to significant cost savings. For instance, utilizing OEM (Original Equipment Manufacturer) parts can minimize downtime and increase machine lifespan by up to 30%.

Moreover, specific applications of these engine parts vary greatly between construction and mining contexts. Construction projects often require faster cycle times and higher maneuverability, driving engineers to select lightweight yet durable components that enhance speed without compromising strength. In contrast, mining operations prioritize heavy-duty and robust engine parts capable of withstanding extreme conditions, as highlighted in a 2022 report by the Mining Association, which states that over 40% of equipment failures are linked to substandard parts. This illustrates the vital need for strategic selection of excavator engine components tailored to the unique demands of each application.

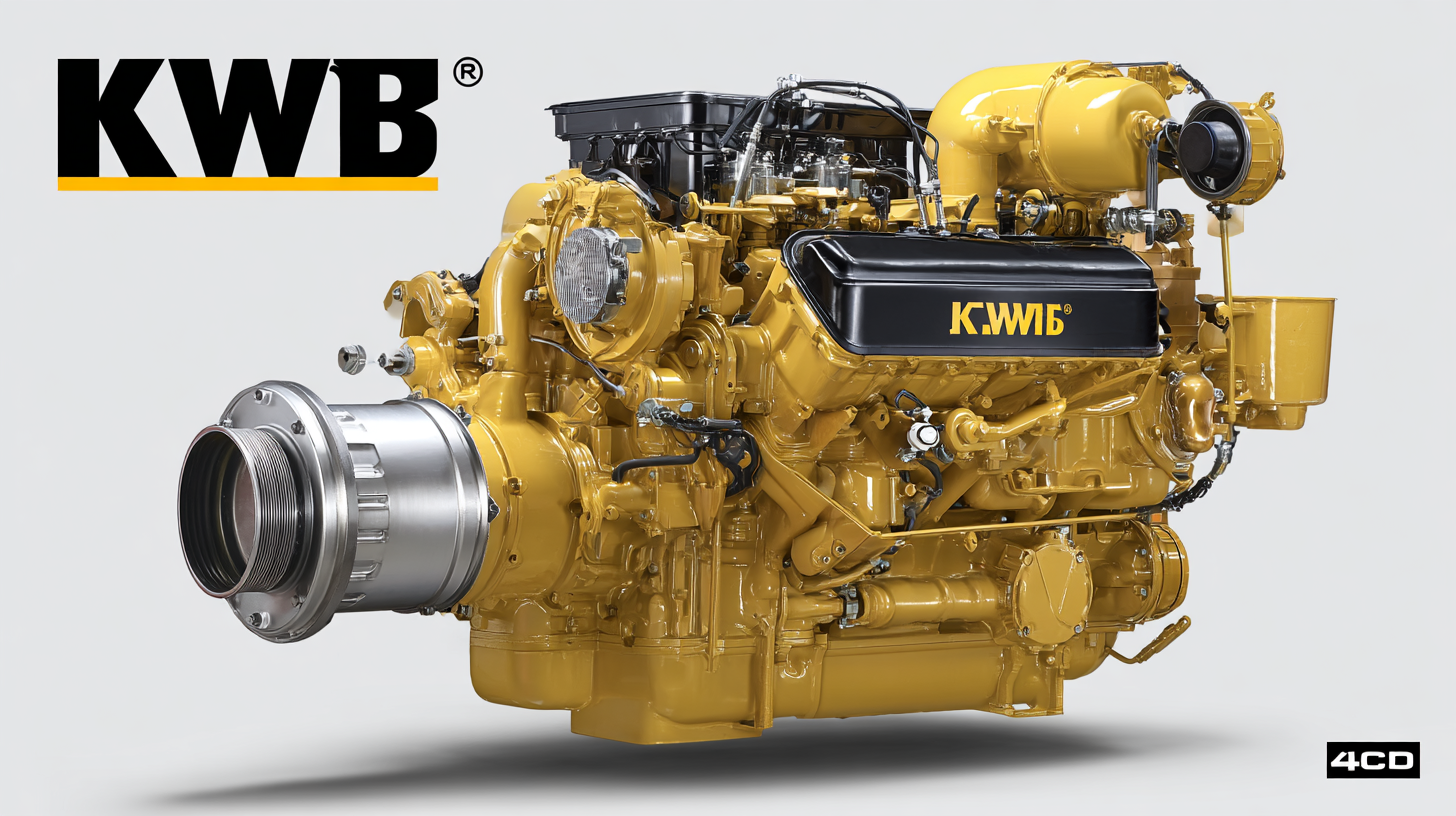

Key Engine Specifications to Consider When Choosing Excavator Parts for Efficiency

When selecting engine parts for your excavator, understanding key engine specifications is crucial for ensuring optimal efficiency and reliability. First and foremost, consider the engine power output. This specification defines the excavator's performance capabilities, so choosing parts that can handle the power requirements is essential. Parts like fuel injectors and pumps must match the engine's horsepower and torque characteristics to avoid underperformance or mechanical failure.

Another critical specification to examine is the engine's displacement. This measurement indicates the engine's size and its ability to produce power. Larger displacement engines generally offer better torque, increasing productivity in heavy-duty applications. Additionally, pay attention to compatibility with your excavator's model and manufacturer. Using OEM (Original Equipment Manufacturer) parts can often lead to better performance and longevity, as these parts are specifically designed for your engine's needs. Analyzing these specifications will help guide you toward making informed decisions that enhance your excavator's overall operation.

7 Essential Tips for Choosing the Best Excavator Engine Parts

| Specification | Importance | Recommended Value |

|---|---|---|

| Engine Power (HP) | Determines the overall performance of the excavator | 75 - 100 HP |

| Displacement (L) | Affects torque and engine efficiency | 4.0 - 6.0 L |

| Fuel Type | Impacts operational costs and engine efficiency | Diesel |

| Turbocharged | Increases power output without increasing engine size | Yes |

| Cooling System Type | Affects performance and longevity of engine parts | Liquid Cooling |

| Maintenance Interval (hours) | Key for maintaining engine performance | 500 - 1000 hours |

| Warranty Period | Indicates manufacturer's confidence in engine durability | 2 - 5 years |

Comparative Analysis of Aftermarket vs. OEM Excavator Engine Parts Reliability

When it comes to choosing between aftermarket and OEM excavator engine parts, reliability is a paramount consideration. OEM parts are manufactured by the original equipment manufacturer, ensuring that they meet the exact specifications of your excavator. This means they often come with a reliable warranty, providing peace of mind for operators. On the other hand, aftermarket parts can be a cost-effective alternative, but their quality may vary significantly. It’s crucial to research the manufacturer’s reputation and read customer reviews before making a purchase.

One essential tip for selecting engine parts is to ensure compatibility with your excavator model. Whether you opt for OEM or aftermarket parts, they must fit perfectly to avoid performance issues. Additionally, consider sourcing parts from authorized dealers to guarantee authenticity and quality assurance. Furthermore, understanding the specific performance standards required for your excavator will help you make an informed decision, ensuring longevity and efficiency in your operations. Always weigh the pros and cons of both options to determine which aligns best with your operational needs and budget.

Maintenance Best Practices for Maximizing Lifespan of Excavator Engine Components

When it comes to maximizing the lifespan of excavator engine components, consistency in maintenance is key. Regular inspections are essential to identify any potential issues before they escalate. This means checking for leaks, unusual noises, or changes in performance. Setting a maintenance schedule tailored to the specific needs of your excavator can help prevent costly breakdowns and extend the life of your engine parts.

Another vital aspect is using high-quality lubricants and fluids. Proper lubrication reduces friction and wear on engine components, ensuring they operate smoothly. It’s also important to replace filters regularly, as clean filters help maintain the integrity of fluids, further protecting the engine. Investing in quality engine parts from reputable suppliers can significantly enhance durability and performance, making it a critical consideration when choosing replacement components.

Incorporating these best practices into your routine not only boosts the reliability of your excavator but also ensures that you’re getting the most out of your investment. Staying proactive with maintenance allows for early detection of wear and can help avoid costly repairs down the road.