Innovative Technologies Shaping 2025 Future with Best Factory Advantages

As we look toward 2025, innovative technologies are set to redefine the manufacturing landscape, presenting unparalleled advantages for what we have come to know as the "smart factory." According to a report by McKinsey, companies that adopt advanced manufacturing technologies can achieve productivity improvements of up to 20-30%. Furthermore, Gartner predicts that by 2025, 75% of factories will integrate artificial intelligence to enhance operational efficiency and decision-making processes. These advancements not only streamline production but also contribute to sustainable practices, with the International Energy Agency estimating that digital transformation in manufacturing could reduce global energy consumption by up to 25%. Embracing these technologies will enable factories to respond more agilely to market demands while simultaneously improving safety and reducing costs, marking a critical shift in how we perceive and operate within the manufacturing sector.

The Rise of Smart Factories: Revolutionizing Manufacturing in 2025

The landscape of manufacturing is set to undergo a significant transformation by 2025, largely driven by the rise of smart factories. According to a report by the International Data Corporation (IDC), investments in smart manufacturing technologies are projected to exceed $500 billion globally by 2025, with more than 70% of manufacturers adopting advanced analytics and IoT solutions. These technologies are not only enhancing efficiency but also improving product quality and reducing time-to-market, creating a competitive edge for early adopters.

Smart factories leverage innovative technologies such as artificial intelligence, machine learning, and robotics to create highly automated and interconnected environments. A study by McKinsey & Company reveals that companies implementing these technologies can achieve productivity gains of up to 30% within the first year. Moreover, the integration of real-time data analytics enables manufacturers to optimize their supply chains, respond swiftly to market changes, and make informed decisions that drive growth. As we approach 2025, the transition to smart manufacturing will redefine operational excellence and reshape the future of the industrial sector.

Sustainability in Manufacturing: Innovations for a Greener Future

In the quest for sustainability, the manufacturing sector is embracing innovative technologies that are significantly redefining production processes. One of the foremost advancements is the integration of smart sensors and IoT (Internet of Things) devices that monitor energy consumption and waste in real time. This data-driven approach not only enhances operational efficiency but also minimizes environmental impact, allowing factories to adjust processes on the fly and reduce their carbon footprint. By utilizing these technologies, manufacturers can streamline operations while promoting a sustainable approach to production.

Moreover, the rising adoption of renewable energy sources is transforming factories into eco-friendly powerhouses. Solar panels and wind turbines are becoming common sights around manufacturing plants, enabling them to harness natural resources for energy. This shift not only lowers operational costs in the long run but also aligns with global environmental goals. Alongside this, innovative materials science is paving the way for the development of eco-friendly materials that reduce waste and enhance recyclability. As the manufacturing industry continues to evolve, these innovations are not merely beneficial; they are essential for creating a greener future.

The Role of AI and Automation in Enhancing Factory Efficiency

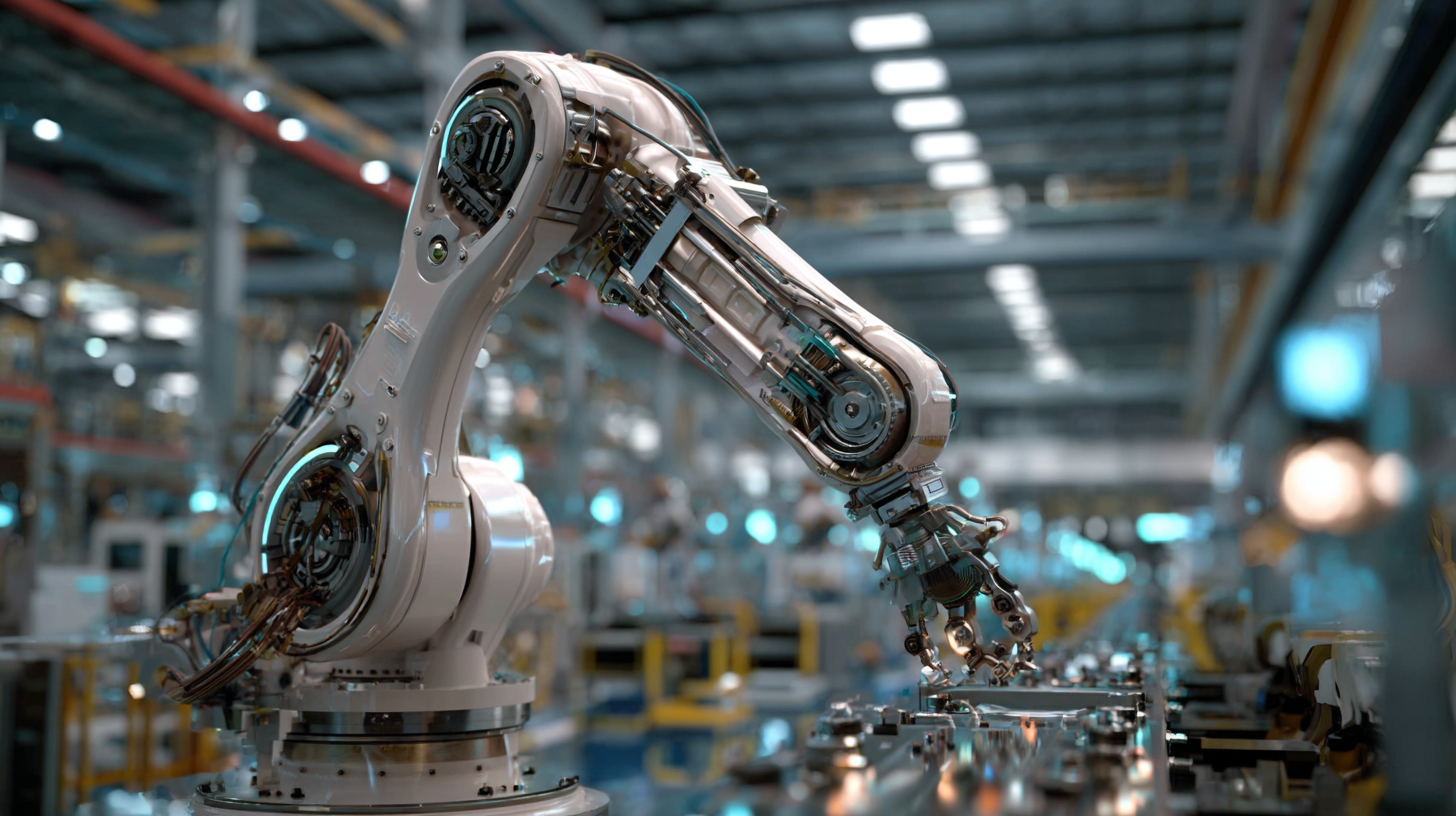

As we move towards 2025, artificial intelligence (AI) and automation are at the forefront of revolutionizing manufacturing processes. These innovative technologies empower factories to achieve higher efficiency and productivity by optimizing workflows and reducing human error. AI algorithms analyze vast amounts of data to identify patterns, predict maintenance needs, and enhance supply chain management, ensuring that resources are allocated effectively and downtime is minimized.

Moreover, automation streamlines repetitive tasks, allowing human workers to focus on more complex and value-added activities. By integrating robotics into production lines, factories can boost their output while maintaining strict quality control. The combination of AI and automation not only accelerates production rates but also promotes a safer work environment, as machines handle hazardous tasks. With these advancements, factories are transforming into smart manufacturing hubs, equipped to meet the demands of an ever-evolving market landscape.

Innovative Technologies Shaping 2025 Future with Best Factory Advantages

Integrating IoT in Production: A Game Changer for Real-Time Monitoring

The integration of the Internet of Things (IoT) in production processes is revolutionizing real-time monitoring capabilities, positioning manufacturers to optimize their operations like never before. IoT facilitates the seamless connection of various components, including processors, sensors, and connectivity modules like Wi-Fi and Bluetooth. This interconnected ecosystem allows for instantaneous data collection and analysis, enabling businesses to respond to operational changes promptly. As the manufacturing landscape becomes increasingly complex, leveraging IoT technologies is not just an advantage; it's becoming a necessity.

According to market analyses, the manufacturing execution systems (MES) market is expected to surpass $15 billion by 2024, with a compound annual growth rate (CAGR) of 10.2% anticipated between 2025 and 2034. This growth underscores the rising demand for systems that can handle the intricate workflows of modern production environments. The 2025 Hannover Messe highlights several key IoT trends, including the integration of generative AI and the emergence of agent-based AI, further enhancing the data-driven decision-making capabilities within factories. By adopting these innovative technologies, industries will not only improve efficiency but also enhance their competitive edge in a rapidly evolving market.

Embracing 3D Printing: Transforming Traditional Manufacturing Processes

Embracing 3D printing is revolutionizing traditional manufacturing processes, paving the way for unprecedented efficiencies and customization.

According to a report by SmarTech Analysis, the global 3D printing market is projected to reach $35.6 billion by 2024, primarily driven by its application in industries such as aerospace, automotive, and healthcare.

This technology allows manufacturers to produce complex geometries that are often impossible to achieve through conventional methods, significantly reducing material waste and production costs.

Embracing 3D printing is revolutionizing traditional manufacturing processes, paving the way for unprecedented efficiencies and customization.

According to a report by SmarTech Analysis, the global 3D printing market is projected to reach $35.6 billion by 2024, primarily driven by its application in industries such as aerospace, automotive, and healthcare.

This technology allows manufacturers to produce complex geometries that are often impossible to achieve through conventional methods, significantly reducing material waste and production costs.

In addition, the adoption of 3D printing can drastically shorten product development cycles.

A study by Deloitte indicates that companies employing additive manufacturing can reduce production time by as much as 90%, providing them with a critical competitive edge in fast-paced markets.

This transformation not only enhances the ability to respond to consumer demands with agility and precision but also fosters innovation by enabling prototyping and iteration at an accelerated rate.

As industries prepare for the future, 3D printing stands out as a cornerstone of modern manufacturing, aligning with the best factory advantages sought for 2025 and beyond.